By Ned Daly

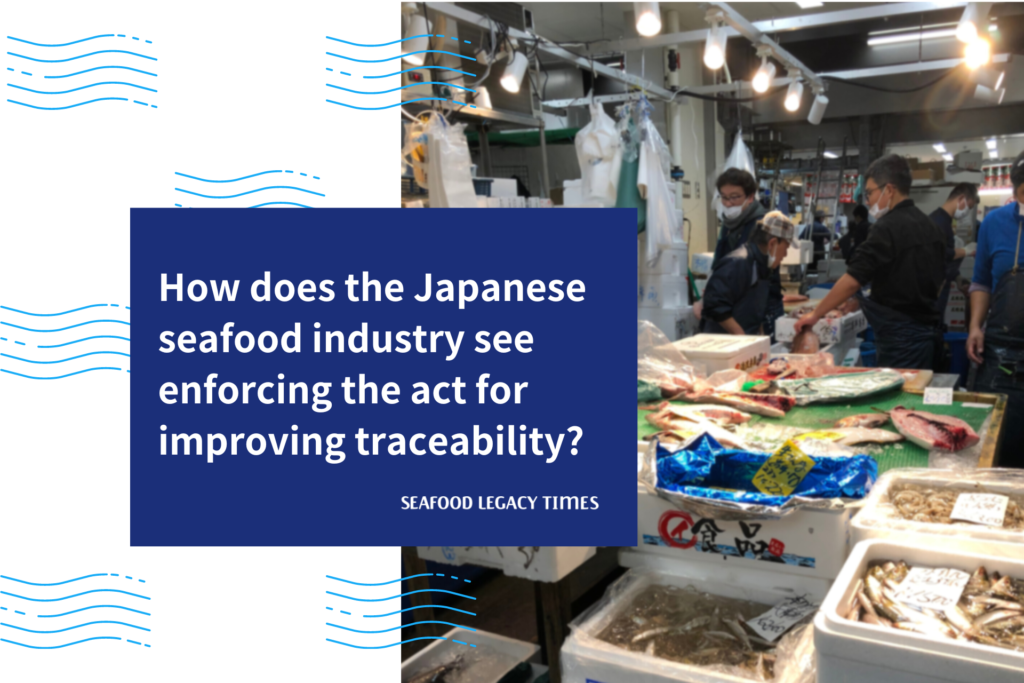

Japan’s seafood industry is rapidly changing. For example, a 2020 fisheries law significantly changed guidance around effective practices in fisheries management. Japanese producers and harvesters, meanwhile, are increasingly adopting measures to provide assurances of responsible supply geared both toward the domestic market – where consumer interest in sustainable seafood is growing – and the export market, with the latter market experiencing a swift upsurge as domestic consumption has dwindled.

Nichirei Corporation is one company aiming to adapt to these changes. Founded in 1942 with the financial support of fishing companies . With over 80 subsidiaries and affiliates worldwide, its businesses include processed food, logistics, seafood, meat, poultry, and biosciences.

SeafoodSource spoke with Wataru Tanabe, who is Nichirei’s director, senior executive officer, and president of Nichirei Fresh Inc., about how a company dealing with so many moving parts handles its policies regarding environmental and social sustainability.

This is the second in a series of five Seafood2030 interviews focused on exploring the growing influence of sustainable practices and responsible management on Japanese seafood production, completed in conjunction with Seafood Legacy, which provided assistance with translation. Founded in 2015, Seafood Legacy is a nonprofit organization offering sustainable seafood consulting and platforming services to Japanese seafood businesses and government entities.

Seafood2030 has sustainability resources translated into Japanese available for companies here.

SS:The Nichirei Group has grown into a major player in the overall Japanese food sector, but its roots are in seafood, right?

Tanabe: The Nichirei Group was founded in 1942 amid the wartime food shortage. It all began when the government brought together fisheries companies and formed Teikoku Marine Products Control Company in order to manage food supplies in Japan.

Seadood delivery scene

Seadood delivery scene

After the war, the company’s name was changed to Nippon Reizo, and the company played a part in the reconstruction of the nationwide food supply chain system starting in 1945. Once Japan’s postwar economic boom got into full swing in the 1960s, the Japanese diet began to Westernize, and the company diversified by adding meat and poultry to its product lineup, as well as getting into the seafood-processing business.

In the 1980s, the demand for more convenient frozen foods increased alongside the women’s empowerment and/or the increasing prevalence of microwave ovens in households. We maintain the top market share by developing products one after another that meet the needs of the times.

In 2005, Nichirei sped up its business management by becoming a holding company. At present Nichirei Foods, a food processing business; Nichirei Logistics Group, a temperature-controlled logistics business; Nichirei Fresh, a meat, poultry and marine products business; and Nichirei Bioscience, business of diagnostic products used in medicine. The marine products business, combined with the meat and poultry business, is operated by Nichirei Fresh.

Could you tell me a bit more about Nichirei Fresh’s business activities?

Tanabe: Nichirei Fresh’s business development is centered around using its global procurement and development capabilities to supply meat, poultry, and marine products. We produce and sell our products processed to an appropriate degree based on the requirements of customers.

We’re also developing new and original “premium ingredients” based on our original six commitments of freshness, deliciousness, safety, security, health and sustainability. In all our activities, we aim to build up well-managed resources and an environmentally friendly, sustainable supply chain and produce greater value for consumers.

What does your seafood business look like in Japan and abroad?

Tanabe: In Japan, we have our corporate headquarters in Chuo-ku, Tokyo, two branch offices that handle seafood sales, and four other branches. We also have two seafood processing plants. Overseas, we have a total of five sales offices in U.S.A., China (Dalian, Shandong, and Hong Kong), and Vietnam, as well as one seafood processing plant in Vietnam.

SS: Your approach to sustainability goes beyond the typical efforts from companies to simply reduce negative impacts. Can you expound a bit on these efforts?

Tanabe: The 78th anniversary of the Nichirei Group’s founding will be in December this year, and we’ve been committed to solving the social problems of the day for all 78 of those years. Providing society with products and services that create new value, creating food culture that has never existed before, continuing to take on greater challenges -, and being a food industry leader is in our DNA it’s what we’re the best at. In the Nichirei pledge, it states that we constantly strive to create new products and services, while pursuing business activities that help solve issues faced by our customers and communities.”

SS: Can you share some examples of activities your company is taking from both an environmental and social perspective?

Tanabe: Let me give you two examples of marine resource sustainability activities Nichirei Fresh has carried out together with stakeholders in Japan.

The first is the Inochi-no-Umi Project, which began in June 2022 in cooperation with the Fukuoka Uoichiba Co., Ltd) and the Amakusa Fisheries Cooperative. This project is funded by revenue from the sales of shiba shrimp caught in Amakusa and aims to regenerate an eelgrass field.

Eelgrass fields are spawning grounds for fish and shellfish and play an important role in the ocean’s ecosystem. However, recent years have seen a continued loss of eelgrass, resulting in damage to their undersea environment and a reduction in water quality. At Nichirei Fresh, we’re using the know-how and experience we’ve gained overseas to actively participate in activities that help solve this problem in Japan, protect the ocean’s ecosystem and marine environment, and contribute to sustainable marine product procurement.

The second is a project titled “Tree Planting Activities to Increase Fish,” which is led by the OUM Fisheries Cooperative. This activity is carried out every year by many fishery cooperatives in Hokkaido, and our company participates in enriching the environment along the Horonai River, which runs near a salmon and trout hatchery in the Horonai area.

By doing so, we aim to improve the salmon and trout homing rate, as well as restore the sea environment, leading to an increase in many types of fish. This was done for the 28th time in 2023, and around 100 people participated, including both Nichirei Fresh employees and local residents. This year, they planted 700 trees, mainly water oaks, reaching a cumulative total of 25,200 trees planted throughout the project’s duration.

Planting 25,200 trees cumulatively in Hokkaido throuth Planting tree project for increasing fish stock

Planting 25,200 trees cumulatively in Hokkaido throuth Planting tree project for increasing fish stock

SS: Are you engaged in any sustainability projects overseas?

Tanabe: We’re involved in marine resource sustainability projects with our overseas stakeholders as well. I’ll again give you two examples.

One is a mangrove tree planting project, Inochi-no-Mori project, in Indonesia. Nichirei Fresh, our shrimp supplier, and the city of Tarakan in North Kalimantan on the island of Borneo started this project in 2006. We see the damage to the environment and the effect on biodiversity of intensive shrimp farming as a social problem, and with this project, we aim to reduce the environmental impact of shrimp farming, as well as make shrimp procurement safe, secure, and sustainable.

Specifically, we take a portion of the sales of shrimp produced from extensive farming, which has been carried out in Indonesia since ancient times, to finance the mangrove trees. We also carry out coordinated tree planting in such places as abandoned ponds that were formerly used in intensive shrimp farming and local parks. We’re currently working with local suppliers to expand this project on the islands of Java and Sumatra.

As of 2022, after 16 years of continuing this project, we have planted a total of over 380,000 mangrove trees. We’ve also seen recovery in the soil and ecosystem of Tarakan and the surrounding areas as a result of this project.

The other example of an overseas project entailed striking a balance between protecting biodiversity and sustainable production to achieve the very first Marine Stewardship Council (MSC) fishing certification of clams in China.

Roughly 60 percent of asari clams imported into Japan come from the wetlands of China’s Yellow Sea coast. Nichirei Fresh has imported these Chinese asari clams since 2006 as one of our “premium ingredients” but we’ve been concerned about declining catch rates and damage to the natural environment. In 2016, our desire to achieve sustainable asari clam procurement aligned with the World Wildlife Federation’s statement on protecting biological diversity on the Yellow Sea coast, so we launched a fishery improvement project (FIP) along with Dandong Taihong Foodstuff, our asari clam supplier.

This project bore fruit, as we received MSC certification in September 2021. Asari clam fishing in the Yalu River estuary area was recognized as being sustainable and friendly to the rich environment of the Yellow Sea coast, which serves as a place for migratory birds to rest and find food. This MSC certification, which was the result of a cooperative fishing improvement effort among members of the China-Japan supply chain, was the first ever awarded in China.

In our commitment to sustainable marine products, Nichirei Fresh aims to increase the share of our products that have MSC fishery certification, Aquaculture Stewardship Council (ASC) certification, and other similar certifications to 50 percent by 2030.

Champion in the collaboration category of the 4th Japan Sustainable Seafood Awards (2022). Second from left: Takayuki Yoshihara, Director and Managing Executive Officer, Nichirei Fresh Inc.; third: Hideki Kunita, Nichirei Fresh Inc..

Champion in the collaboration category of the 4th Japan Sustainable Seafood Awards (2022). Second from left: Takayuki Yoshihara, Director and Managing Executive Officer, Nichirei Fresh Inc.; third: Hideki Kunita, Nichirei Fresh Inc..

SS: There is an increasing focus on forced labor and human rights in seafood. How are you carrying out due diligence around human rights issues?

Tanabe: Marine products are an important resource supporting Nichirei Group’s business activities. Recently, however, numerous problems have been identified, such as the effects of climate change, overfishing, bycatch, destruction of forests and natural habitats, and human rights violations by fishing industry members.

At the Nichirei Group, we are actively working toward solving marine product sustainability problems in our supply chain, and in order to aim for the realization of a sustainable society, we established the “Nichirei Group Sustainable Marine Product Procurement Guideline”s in April 2023, as well as new key performance indicators as a goal. One excerpt from those guidelines is to appropriately conduct due diligence to confirm whether human rights are respected in the fisheries supply chain.”

We’ve received advice from Seafood Legacy ever since drafting those guidelines, and they’ve been very understanding and empathetic from the very beginning. Recently, as both of our desires to construct a sustainable marine product supply chain aligned, we decided to launch a collaborative project aimed at developing due diligence specifically for regarding human rights in the seafood product supply chain.

This is a two-year project for 2023 and 2024, and the intent is to produce a human rights due diligence program tailored to our suppliers in the fishing industry that includes a human rights auditing method. It employs the human rights principles of the Monterey Framework and applies to three categories of suppliers: natural seafood products, aquaculture products, and processed seafood products.

We performed a human rights audit trial and designed a pilot model for aquaculture and processed seafood product suppliers in 2023. In 2024, we’ll be doing the same for natural seafood product suppliers.

SS: I see you’re involved in a wide variety of activities, reaching even as far as production of seafood products.

Tanabe: One more of our marine resource sustainability activities is putting effort into raising awareness within our company. As one part of these efforts, we launched the “SDG Activities that Start in the Employee Cafeteria” program to use the employee cafeteria, a very familiar place to our employees, as an opportunity to teach them the importance of passing on sustainable food to the next generation.

The first phase of this project was to receive CoC certification and add ASC-certified shrimp that our company procures and sells to the menu of our corporate headquarters’ cafeteria, which was carried out once this July and twice this September. For the second phase, we plan to add MSC-certified asari clams to the menu in December. This project was launched in our corporate headquarters (Tokyo) and other branches in the Kanto area in 2023 and starting in 2024 we are aiming to roll it out to all Nichirei Group employee cafeterias outside the Kanto area.

SS: At Nichirei, you’re not just investing in sustainability, but prioritizing quality assurance, circularity, transparency, and reporting on commitments toward environmental, social, and governance (ESG) activities. What is the motivation for this investment?

Tanabe: In order to achieve our long-term management goals, we identified five groups of material matters and determined our vision for each. We’ve been carrying out materiality since 2022, and consider achieving a balance of social value through solving social problems and economic value through business growth to be our vision for sustainable management.

One of these five groups is “Realizing sustainable food procurement and circular society”. We identified this as a goal because if we can’t solve various social problems surrounding our supply chain, – the core of our business, – and contribute to sustainable food procurement and a circular society, then we won’t be accepted by society, and we won’t be able to sustain ourselves as a business.

In pursuit of this goal, we’re putting our effort into sustainability education for each level of the company, – from directors to ordinary employees. For example, our directors have study sessions in which they receive the latest information and trends surrounding sustainability, measure its impact on operations, and apply this to our management strategy with both a financial and non-financial viewpoint.

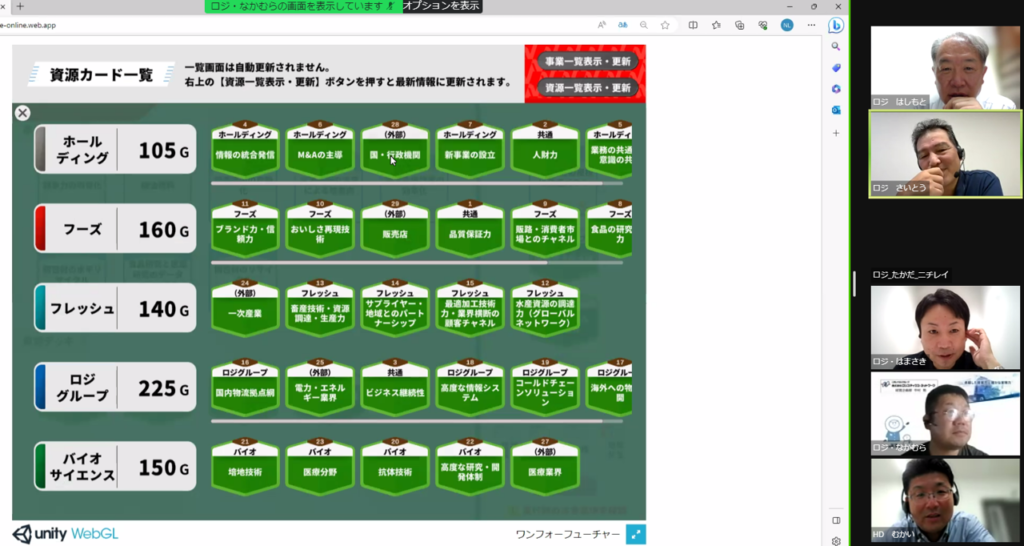

For our managerial staff, comprising roughly 1,300 members, we developed an original training program, titled “One for Future.” In this program, we aim to have the participants understand Nichirei’s sustainability management, as well as obtain a sustainability mindset and change their behavior using simulations that contain a balance of social value through solving social problems and economic value.

The photo of SDGs material training program “One for Future”

The photo of SDGs material training program “One for Future”

This is our ideal style of human resource development and one that ensures each and every employee understands Nichirei Group’s sustainability policy and how their own duties contribute to realizing a sustainable society.

SS: I understand you have marine, meat and poultry suppliers in about 30 countries. From a sustainability standpoint, what are you putting your effort into regarding supply chain management?

Tanabe: We put effort into building a more mutually beneficial partnership, with a particular focus on trust relationships.

Out of all of Nichirei Fresh’s suppliers, almost 70% are ones that agree with our mission, our six commitments, our thoughts about sustainability, etc. and have done business with us for quite some time. Our relationships with these suppliers have lasted for 20 years or more on average, our longest-running supplier has been with us for over 40 years.

In order to deepen our trust relationships, Nichirei Fresh has our employees frequently visit our suppliers and talk to them. By repeatedly working together to solve both of our problems one at a time, we make our partnership much stronger.

SS: Do you think about sustainability, assured supply, socially responsible activities, and risk reduction separately or as a unified core priority of Nichirei?

Tanabe: We apprehend sustainability as the core of our business. According to “Compass Rose 2024,” – our medium-term business plan that began in 2022, – our company aims to expand its business activities as a whole based on the Nichirei Group Sustainability Policy. While performing our societal duty to be a company that supports rich dietary lifestyles, we aim to improve our social and economic value through the acceleration of sustainability management and the pursuit of capital efficiency.

Also, starting on April 1, 2023, we’ve been working toward a 100 percent procurement ratio of products that meet the sustainable marine products guideline and a 50 percent procurement ratio of MSC and ASC-certified products by 2030.

──In terms of sustainability, what is Japan’s fishing industry’s strength? Also, what do you think are its issues going forward?

Tanabe: The fishing industry is a globally growing one. Communicating the value of our products through the power of branding like “premium ingredients” is our reason to exist as a company, and I believe it will also connect to bring sustainability to Japan’s fishing industry.

SS: Moving forward, what sustainability issue does your company want to put particular effort into, and how will you contribute to solving that issue?

Tanabe: We foresee a depletion of seafood resources and a tightening of restrictions on fishing locations and quotas due to rising water temperatures. In the face of these issues, we aim to pour our efforts into developing a sustainable supply chain and living in harmony with the environment, human rights, and local communities.

As such, we seek to realize the following two goals.

1. To see the full possibilities of materials and “cooling power” – meaning the ability to ensure the long-term storage of food and, at the same time, preserve the original quality of the raw ingredients used – and contribute to the Earth’s future and the soul and health of its people through food.

2. To extend our consumers’ healthy life expectancy by providing them with high-quality animal protein and contribute to the formation of a sustainable society by supplying our environmentally-friendly premium ingredients.

In order to reach these goals, we will continue to expand our business activities with the cooperation of our stakeholders, and we kindly ask for your continued support.

Read on SeafoodSource >>>Nichirei Fresh President Wataru Tanabe tackles sustainability and human rights due diligence

-1024x606.png)

_-1024x606.png)

1_修正524-1024x606.png)

.2-1024x606.png)

2-1024x606.png)

-1-1024x606.png)

Part2-1024x606.png)

Part1-1024x606.png)