Efforts to promote sustainable seafood are gaining momentum in Japan.

In 2020, the Fisheries Law was revised for the first time in 70 years to clearly state the importance of enforcing stock management, and in 2022, the Act on Ensuring the Proper Domestic Distribution and Importation of Specified Aquatic Animals and Plants came into effect, marking a major step toward eliminating IUU (Illegal, Unreported, and Unregulated) fishing. Companies are also working towards obtaining Chain of Custody (CoC) certification, and efforts are underway to establish guidelines to resolve human rights violations and IUU fishing issues.

However, not least because of the language barrier, these efforts are not well-known yet outside Japan.

This is why this year, the Seafood Legacy Times has partnered with SeafoodSource, a leading seafood industry media outlet in North America and Europe, to launch the “Japan: How Sustainability and Changing Markets are Impacting Seafood Production” series to communicate the outstanding efforts of the Japanese government, companies, and fishermen to the rest of the world.

This first part of the series introduces the world’s and Japan’s first BAP-certification initiative for red sea bream.

・ ・ ・ ・ ・

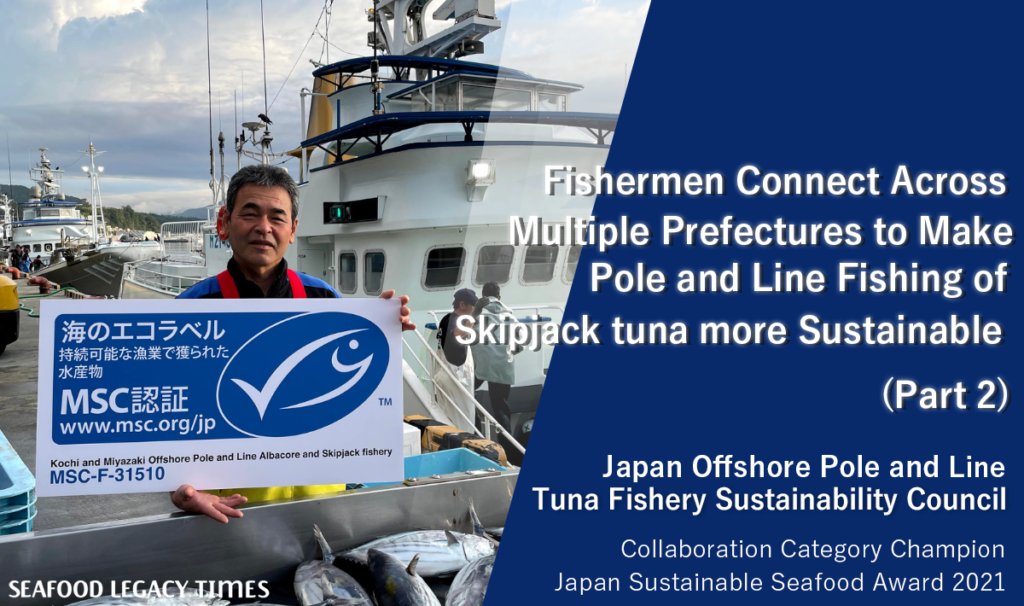

In March 2023, Ainan Fishery Cooperative Association, Yasutaka Suisan Co., Ltd., and Hamasui Co., Ltd. were the first in the world to receive BAP certification for red sea bream. This was the first BAP certification for any kind of fish in Japan.

The Ainan Fisheries Cooperative members produce approximately 20% of Japan’s red sea bream total production. We spoke with Mr. Takahiro Okada, General Manager of the Sales Promotion Department of the Ainan Fishery Cooperative Association, who led the certification activities, and Mr. Takami Yasuoka, Representative Director of Yasutaka Suisan Co., Ltd to share their thoughts on sustainability and the future of Japanese fisheries.

(Titles omitted)

Editor: Recently, we have seen a number of changes that affect producers in the Japanese seafood industry: the revision of the Fisheries Law, increased interest in exports due to declining domestic consumption, and growing awareness about sustainability by consumers in Japan and abroad. How has the Ainan Fisheries Cooperative responded to these changes?

Ainan Fisheries Cooperative/ (hereinafter, Okada): In 2017, the Ainan Fisheries Cooperative obtained AEL (Aquaculture Eco-Label) certification for all 10 of our fish species (including red sea bream, yellowtail, greater amberjack, and striped jack), and the Cooperative has worked with producers to promote sustainable aquaculture. Our group also received MEL aquaculture group certification for red sea bream and MEL CoC certification at the Hamasui processing plant in 2020.

Editor: What motivated your early efforts to obtain certification?

Okada: For some time, Ainan Town, the Fisheries Cooperative, and Ehime University have worked together to address issues in the fishery industry, for example, the early detection of red tides. In particular, we have collaborated closely with producers to share production methods and create instructional manuals. The initiative to obtain a third-party certification verified the good work being done and helped increase the credibility of our efforts.

Editor: You now received BAP certification for around 300,000 red sea bream. What made you decide to obtain this certification?

Okada: We have exported red sea bream to the U.S. since 2019. When considering which global standard eco-label certification we wanted to obtain, we chose BAP certification because of its popularity in the U.S. and its costs. Another reason was that no one else in Japan had received BAP certification yet.

Editor: Were there any reactions to you receiving BAP certification?

Okada: We received business offers from foreign hotels and other businesses which whom we had not really been connected before. There were also many inquiries during The Tokyo 2020 Games, and we feel that the BAP certification has created high expectations for us.

Editor: Along with the market value, what value does certification have for Japanese fishermen?

Yasutaka Suisan/ Yasuoka: I think the certification proves we are working on sustainability. With sustainability, it is necessary to involve a third party in the assessment because it is difficult to tell whether a company does things properly or not from only self-reporting.

Awareness of the value of manufacturing in Japan has always been high, and simply being “Made in Japan” increased the trust of customers in a product. In this sense, it is rather disappointing to see that a growing number of distributors and retailers will not do business with you unless you have a certification and that the label “Made in Japan” is no longer recognized as a value.

Japanese consumers’ awareness of sustainability is still not very high. Still, we hope they will understand the value of the strict certification we obtained and choose our products.

Okada: I believe it guarantees food safety and security and will become a passport for exporting. Sustainability initiatives for the environment and human rights are also particularly connected to regional sustainability. A challenge in the future will be how to enhance sustainability in our region while acquiring certifications from overseas.

Also, Fishery is the core industry in Ainan. I think obtaining certification and taking action is necessary to promote a sustainable local industry.

The BAP-certified red sea bream will bear the “Ainan Sea Bream” logo. We are working on obtaining design trademarks in the U.S., Canada, and other countries, and we want to make the name “Ainan” known around the world.

Editor: What issues came up in the BAP certification process?

Yasutaka Suisan/Yasuoka: We were required to reduce the amount of fish in the feed used for our aquaculture as much as possible, but since fish essentially eat other fish, I think it would be better to make effective use of fish raised in the wild as well. However, it is important to ensure a proper balance and not catch too many wild fish.

One of the criteria for certification is not using antibiotics. Although our company has never used antibiotics, some antibiotics are approved for use in Japan but not in other countries. I felt that adjustments and alignment should be made at the national level on this point.

Okada: Along with the huge amount of time needed to translate English texts, there are many differences in common practices between Japan and other countries. For example, we needed to undergo inspections by inspection bodies that were not required in Japan, and there were categories we do not usually deal with in Japan. We thought that the process would be smooth since we had obtained the MEL, but that was not the case.

It was extra difficult because we were doing this on our own, but we used our past know-how to tackle the problems. The certification for the processing plant was especially difficult because there were many things we dealt with for the first time.

We have been cooperating for a long time with the Town of Ainan Ainan Town, the town’s fish disease inspection laboratory, and university research institutes, so it was easy for us to obtain scientific expertise. I think this kind of support was a big help in getting the certification.

Editor: What do you feel are the differences between the U.S. and Japanese markets?

Okada: I think there is a market for certified products, including in general retail, in the U.S., while in Japan, an understanding of these kinds of products is still lacking. Having certified seafood in Japan is not yet seen as a value justifying a certain price. There are pricing and standards problems in the U.S., too, but I get the sense that if you obtain a certification, you are able to join the playing field.

There is also the issue of obtaining CoC certification. Still, since BAP does not require CoC certification at the distribution stage, I think it holds the potential to be more widely adopted.

Editor: What are your plans for the future?

Okada: We would like to participate in overseas events such as the Seafood Expo North America, hold fairs, and other activities to promote and sell our BAP-certified “Ainan Red Sea Bream” in overseas markets. We also hope to work together with producers to apply these practices to other kinds of fish and expand the number of certified fish species in the future.

We do not use any antibiotics to raise our “Ainan red sea bream.” Thanks to the Kuroshio Current, we are blessed by an environment that allows us to grow fish without relying on antibiotics, but even so, it takes a lot of time and effort to reduce the density and control the feeding of the fish.

We will continue our efforts to make more people aware of the value of Ainan Fisheries Cooperative’s prized red sea bream in the hope they will choose our safe-to-eat and delicious product.

Read on SeafoodSource >>> Ainan Cooperative, Yasutaka Suisan: Sustainability awareness, changing markets impacting Japanese seafood production

-1024x606.png)

_-1024x606.png)

1_修正524-1024x606.png)

.2-1024x606.png)

2-1024x606.png)

-1-1024x606.png)

Part2-1024x606.png)

Part1-1024x606.png)