The first part of the interview focused on how Fish and Planet came to life and how Mr. Norito first met with seaweed and kelp producers in Jusanhama, Ishinomaki, Miyagi Prefecture, in order to work together with them on the project. He also explained why he chose to focus on seaweed. We will now discuss the challenges involved in acquiring the certification, as well as his plans for the future.

<<< Read Part 1

――Acquiring the certification as a group of volunteers has its own difficulties. What was it like to actually do it?

One of the advantages of being a volunteer group is that we are all working toward the same goal, so it was easy for us to work together. I think it would have been more difficult with an existing organization such as a fishermen’s cooperative, because there are many people with different motivations.

One of the challenges is that you are working without the structure an organization has, so in preparation for the audit, you need to select members, create a roster, organizational chart, and rules and regulations, and you also need an “internal control system” in order to ensure that you can maintain the certification.

If you are a fishermen’s cooperative, you have employees who will take care of the paperwork. But with a group of volunteers, the farmers themselves must do the paperwork. It is not possible for the fishermen to do management and paperwork on their own. So they asked us to take care of the practical side of things.

――So Fish and Planet provided both financial and practical support?

Yes, that’s right. However, the paperwork would be of no use unless it was in line with what was happening onsite, so we had discussions about this with the members of the group, especially with Mr. Abe.

Still, the first thing to do was to answer the member’s questions, “What is the ASC certification, and will it be profitable?” Mr. Abe explained our plan to them and how we would make it profitable.

In fact, it was very late in the process that we finally had our 19 members selected. This was because a major volume retailer was looking for a new site to acquire the ASC and had not waited to acquire it before starting to talk about it. Some people heard about it and started saying they wanted to join.

It was also challenging to create in-house management documents that would meet the ASC’s standards and be adapted to the site. Mr. Abe and his team provided consultation on this as well.

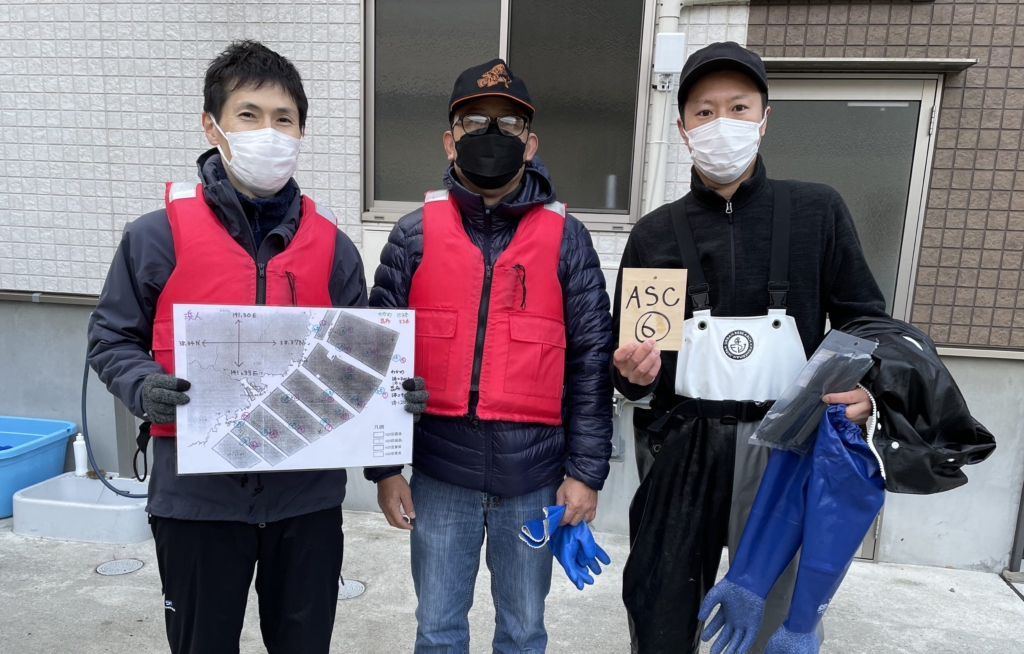

We worked with fishermen at the production site to undergo the ASC certification audit

We worked with fishermen at the production site to undergo the ASC certification audit

――To make international standards fit the reality on the ground, sounds like a difficult task.

That’s absolutely right because it is the producers who are actually audited by the ASC. While discussing things with Mr. Abe, he would say, “According to ASC standards, this is how it should be done,” or “That is just not feasible,” and so on.

For example, seaweed is boiled after harvesting, and the kerosene used for this process is kept in drums located in the boiling facility, and a local gas station comes to refill the drums. The ASC says that if the drums are not “in secondary containment, there is a risk of leakage”. But to add a “secondary containment” to all the drums would involve considerable costs.

There are other issues, like making sure the boiling water doesn’t splash and burn the workers when boiling the seaweed or making sure the workers don’t hurt their backs by standing on their feet too long, and how to take care of those issues… International standards are designed to be applied to companies and their employees, and they are not suitable for family businesses in many ways. Besides, fishermen have always used analog methods, so it is hard for them to fit in there as well.

The majority of fisheries in Japan are family-owned, and that is where we at Fish and Planet are trying to focus our efforts. Small-scale fisheries in the world are not making money, which is why certification is not being pursued, and this has been pointed out as a problem in reports by international organizations.

Seaweed and kelp need to be boiled immediately after harvest.

Seaweed and kelp need to be boiled immediately after harvest.

――How do you distribute the seaweed and kelp once it is ASC certified?

We obtained the certification in early November, and one of our plans is to have our products sold through mass retailers in a variety of ways. We are also in talks with a major convenience store company.

But there are pricing constraints when it comes to mass retailers and convenience stores, so we are marketing to organic supermarkets and consulting with Seafood Legacy Co., Ltd.as well.

First, we would like to establish a firm foothold in Japan, and then expand our business overseas. I have been working with the person in charge of seaweeds at the ASC, and I believe that the ASC will be able to support us in our global business negotiations.

――Is Fish and Planet also responsible for conducting these sales activities?

Mr. Abe is handling the domestic distribution side of the business, so we are cooperating with him to find new sales partners. Fish and Planet is in charge of overseas sales.

As we get going, things will get much busier. I am thrilled with getting the certification and receiving the award, but it is a starting point, and the real work begins now. We have already purchased the seaweed and kelp harvested this spring. Because the harvest is once a year and the next one will be next spring, we have applied for an exception to allow us to apply retroactively.

In addition to retail distribution, we are also making products to be sold under the “Fish and Planet” brand. We are also considering product packaging, including a special packaging design for overseas markets.

――What kind of future plans do you have for Fish and Planet?

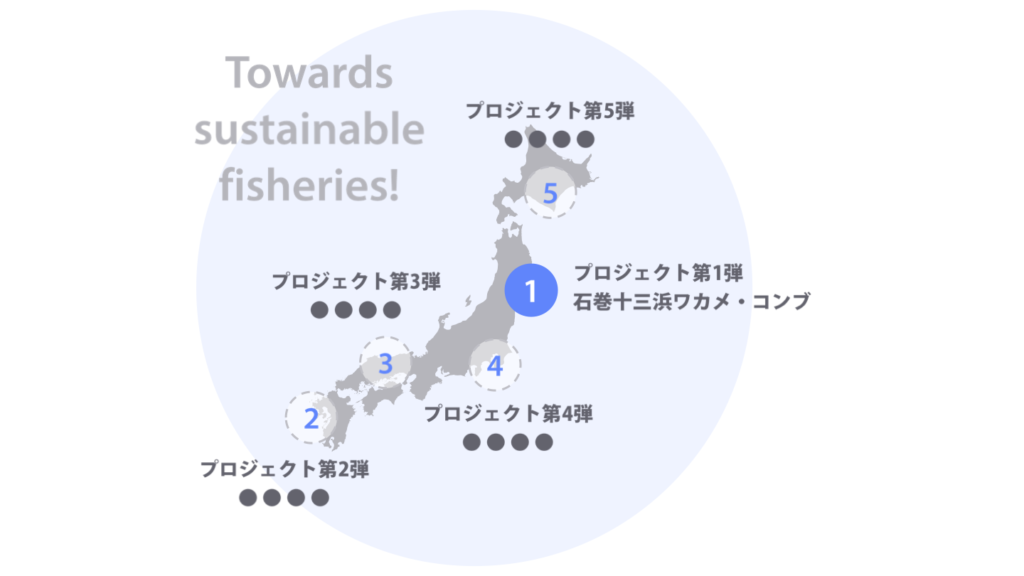

From this year through next year, I want to really focus on selling the seaweed and kelp generated by this project. My plan is to first create a case model in Ishinomaki, and then expand the project to other locations.

Beyond that, I would like to work more seriously on other issues involving fewer producers and dwindling resources. Take, for example, the Ariake Sea laver (“nori”) producers. I hope to work with young fishermen in those areas on similar initiatives. I would like to expand these efforts beyond seaweed.

――What do you mean by beyond seaweed?

Since I am originally the owner of a tempura restaurant, it would be nice if I could work on shrimp and sea eel. Also scallops, for example. As a goal, I would be happy if all of our tempura were made from certified seafood.

Fish and Planet is working with small-scale producers throughout Japan to accelerate the transition to a sustainable fishing and aquaculture industry, providing help with investment, practical support, and sales.

Fish and Planet is working with small-scale producers throughout Japan to accelerate the transition to a sustainable fishing and aquaculture industry, providing help with investment, practical support, and sales.

――Recently, the Japan Consumers Cooperative Union has been supporting the AIP* effort with shrimp from Indonesia, putting a portion of its purchases toward the expenses of the AIP*, and there have been other attempts to support the acquisition of the MSC certification for oysters in the Hiroshima area. There seems to be a commonality in the way that retail and food and beverage companies support the fishing industry. Sellers support production sites, which creates a positive cycle. Do you have any thoughts on what is needed for such efforts to become more common?

This is an issue that I think about as well. The cycle really begins with the consumer being aware of the problem. I think this is why it is so important to communicate through the media.

There are still many challenges to overcome in Japan, but I think we have no choice but to take action. Until about five years ago, I knew very little about the situation, but the more I learn about it, the more I see the depth of the problem. In light of this, I believe that what we at Fish and Planet can do is to continue to take action and to communicate this information to the public as best as we can.

Right now, it may still be difficult for consumers to be on board. Even if the consumers might not respond immediately, there are companies that are beginning to recognize the problem and are increasingly aware of it, so it is important to collaborate with these companies and work together with them rather than separately.

――When it comes to consumer awareness, the volume of information is completely different between companies and consumers. Should the first step be to inform them?

That is exactly the point we need to think about. In the case of seaweed and kelp, there are many people who do not know that they are farmed, some people think they grow in the wild. This is true in Japan and even more so in other countries. The way certification is received also differs from country to country, so we still need to think about how to present and communicate the information.

Hiroshi Norito

As the seventh generation owner of the 190-year-old Ginza Daishin, a fresh fish retailer and tempura restaurant founded in the Edo period (1603-1867) in Asakusa, Tokyo, and now operating in Ginza (now Azabu), he is committed to the sustainable and socially responsible fishing and aquaculture industry and the transmission of Japan’s tempura culture. After graduating from the Tokyo Institute of Technology, he earned a master’s degree in environmental management from Duke University (USA). His previous experience includes M&A advisory work in the investment banking division of Daiwa Securities SMBC (now Daiwa Securities) in Tokyo and New York, before starting his own international e-commerce company.

-1024x606.png)

_-1024x606.png)

1_修正524-1024x606.png)

.2-1024x606.png)

2-1024x606.png)

-1-1024x606.png)

Part2-1024x606.png)

Part1-1024x606.png)